June 8, 2015

9am – 5pm

Ascott, Makati City

Fee: Php 8,000.00 / person plus 12% VAT

- Early Registration Payment: Ten-Percent (10%) Discount if PAID thirty (30) days before the training date

- Group Discount: Five-Percent (5%) on Three (3) or More Participants

[button newwindow=”yes” link=”http://agcconferences.com/?p=3780″ color=”orange” ]Register Now [/button]

[tabs slidertype=”left tabs”]

[tabcontainer]

[tabtext] About [/tabtext]

[tabtext] Course Outline [/tabtext]

[tabtext] Facilitator [/tabtext]

[tabtext] Bank Details [/tabtext]

[/tabcontainer]

[tabcontent]

[tab]

Overview / who should attend and why?

Total Productive Maintenance (TPM) is essential to ensure that your plant and machinery are reliable and don’t breakdown. It is a fundamental tool for any company to ensure that they can hold minimum inventory, respond to customer needs quickly and be efficient. Total Productive Maintenance can help you to eliminate unwanted breakdowns, ensure that the up time of machines is as high as possible, reduce maintenance costs, increase machine efficiency, help to implement team working between functions. Based on techniques used all over the world the course outlines the importance of TPM to any organization. It then shows how to measure performance and understand where your issues are, and then the tools and methodologies associated with TPM. If you are in anyway involved in maintenance or production efficiency then this course is for you.

Course Objectives

- To explain the importance of TPM for any organization

- To enable delegates to understand the methodology for applying TPM and autonomous maintenance

- To be able to measure the effectiveness of machinery (OEE)

- To be able to predict when failures are likely to occur

- To understand how to implement a TPM program in your organization

- To demonstrate the benefits of TPM and how to calculate them in your organization

- To understand the people aspects of deploying TPM in your organization and obtain buy in from your team

- To understand common mistakes and how to overcome them

[/tab]

[tab]

Course Content

- Introduction and admin

- Why is TPM essential in today’s business

- The history of TPM

- Lean and the 8 wastes

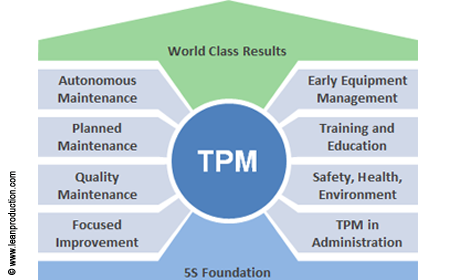

- Pillars of TPM

- Introduction to 5S and visual management

- Understanding the 6 big losses

- The basic concepts of TPM and its goals

- How to measure your current performance levels – Overall Equipment Effectiveness (OEE)

- Roles and responsibility / cultural change

- Motivating the operators and building the team

- How to deploy a TPM program in your business and set targets and goals

- How to calculate the benefits of TPM to your organization

- Common mistakes and how to overcome them

- How do we start?

- Wrap up

Benefits of Attendance

- Improve business performance by increased machine utilization, leading to improved production availability and performance, develop a lifelong plant maintenance program and reduce maintenance costs

- Understand how to set up a more flexible working environment

- Enable the delegate to understand and implement TPM

- Understand OEE and how to use it to drive improvements

- Understand how to predict failures and reduce downtime

- Understand how to collect and analyze data

- Understand how TPM can be linked to other plant improvement initiatives such as Lean

- Understand how to set up a successful TPM program

[/tab]

[tab]

Engr. Joylan Z. Nadal

Engr Nadal graduated with a degree of Bachelor of Science in Electrical Engineering (BSEE) from Saint Louis University. He also took Leadership Management Executive Course at Asian Institute of Management (AIM). He served 18+ years in Multi National and High Technology Industries (including Texas Instrument Philippines Incorporated – 7 years and Intel Technology Philippines Incorporated – 10 years)

After his career stint as an employee of known multi companies, He pursued his career by setting up his own Consultancy Firm (JJN Business Consultancy Service). He had been hired for his services as a Consultant and Technical Trainer/Coach for Operational Excellence, Safety and Quality Systems on Fast Moving Consumer Goods (FMCG) and other known Electronics, Pharmaceutical and Crop Science Industries.

He had been one of the key Facilitator/Trainer of Production Management Association of the Philippines (PROMAP) Public Management Development Program (PMDP). He was also been invited as guest speaker of Marcus Evans Professional Training Consultancy and judge of ASEMEP Q&PC Annual Quality Convention. He was also a former SEIPI-ASEMEP AQ&PC Chairman.

His areas of expertise includes: Operational Excellence and Continuous Improvement (Visual Factory, Lean Manufacturing, Six Sigma, Total Productive Maintenance); System Management Implementation (ISO9001, ISO14001, OHSAS18001, ISO22000 (Food Safety Management System)) Training and Certification; Advance Problem Solving Methodology (Root Cause Analysis, FMEA, DOE, 8 Steps Problem Solving Tools, PM Analysis, TRIZ), Technical Competency Development (Skill level Competency Matrices, Training Need Analysis, Pneumatic Systems, Mechanical Systems, Bolts and Nuts, Electrical System); Safety Training (Incident Injury Free (IIF), Job Hazard Analysis (HIRARC), First-aid and CPCR, Occupational Health and Safety, Environmental Management Awareness and implementation) and Leadership Development Course.

He is certified in the following field such as Lean Six Sigma (Six Sigma Experts), Total Productive Maintenance (JIPM TPM), Lean Master (Dearborn, Michigan), Lead Auditor Trainer and Assessor/Auditor (Management System Auditing (RABQSA-AU), Leading Management Systems Auditing Teams (RABQSA-TL), Quality Management Systems (RABQSA-QM), Environmental Management Systems (RABQSA-EM), Occupational Health & Safety Management Systems (RABQSA-OH) and (IRCA-SGS), Food Safety Management Systems (ISO22000)).

Part in the implementation of Texas Instruments (Phils) Inc. JIPM TPM and

achieved TPM Part II: JIPM Consistent Award and support in the development

of TPM Book Part II (Consistent Award). Champion Lean-TPM-Six Sigma as Site

Manager in Intel Technology Philippines Incorporated. Received numerous major

awards both Regional, National and International (Technical Management Group Award,

Divisional Award, ATM HR OD and Training Functional Award, EHS Recognition Award,

Innovation and Exposition of Quality Circles Convention Gold Award (IEIQC), Gold

Award in Philippines Productivity Improvements Circles Association of the Philippines

(PICAP), Gold and Silver Award in Quality Circles Practitioners Association (QCPA) and

Award for Best Practices in SEIPI-ASEMEP Quality and Productivity Convention.

Currently he is a Corporate Trainer and Consultant of Nutriasia Incorporated, Delmonte Philippines Incorporated, B-Mirk Group of Companies implementing Operational Excellence (Visual Factory and Total Productive Maintenance) Newborn Food Products (TS22002-1 Technical Requirement for Good Manufacturing Practice (GMP) and Food Safety Management Systems (FSMS).

GCERTI Certified Lead Auditor Trainer and Assessor on Systems Management (ISO9001, ISO14001, OHSAS18001, ISO22000).

[/tab]

[tab]

BANCO DE ORO (BDO)

Account Name:

Aguila Group Companies (AGC) Development Corporation

Account Number:

00 543 801 3291

Bank Address:

Alfaro-Salcedo Village Branch, PCCI Bldg., 118 Alfaro St., Salcedo Village, Makati City 1227, Philippines

Swift Code:

BNORPHMM

[/tab]

[/tabcontent]

[/tabs]

Hi Good Afternoon ?

Just want to ask if you have training for the following topic, what is the training date and training fee.

1. Total Productive Maintenance

2. Master Yellow Belt Lean Six Sigma Professional Program

3. Machine Automation Course – P & EP plus PLC

4. Professional Certificate in Facilities management series 1

Thank you for the response ?

Sir/Madam,

Can you send me the schedules of your TPM training for this year 2015.

Thanks

Elbert Abañ0

Funai Cebu

Hi, is there new schedule for TPM this coming Q1-2015? thanks

Yes, we will have, please subsicribe for further notice. thanks

Hi. Are there still open slots for this training? Thank you.